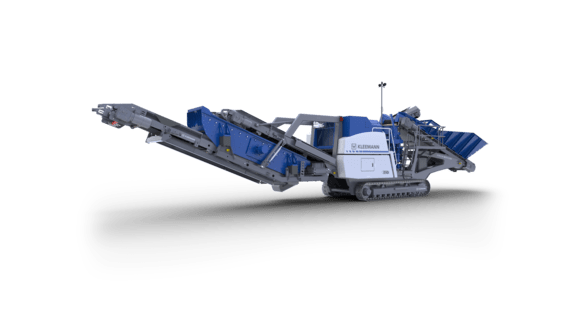

WIRTGEN MCO 9 S EVO Дробилка

Размер корма:

200 мм

Высота откорма:

2650 мм

Высота подачи с расширением:

3080 мм

Емкость питания до приблизительно.:

245 т/ч

Ширина хоппера:

2 580 мм

Ширина хоппера с расширением:

2 580 мм

Длина хоппера:

3560 мм

Длина хоппера с расширением:

3840 мм

Характеристики продукта

ComparedwithMCO9EVO,theMCO9SEVOisequippedwithamorepowerfuldriveunitaswellaslargerrunninggearandchassis.Asanoption,italsofeaturesasecondaryscreeningunit(singledeckvibratingscreen)withreturnconveyor.Thispermitsaclosedmaterialloopandthustheproductionofadefinedfinalgrainsize.Theoversizedgraincanalsobeoptionallydischargedsidewaysviathe100°swivel-mountedreturnconveyor.

Foracontinuouscrusherfeed.

Uniformloadingisindispensableforagoodproduct,optimumthroughputandlowwear.Toensurethatthecrushingchamberisalwaysevenlyfilled,theContinuousFeedSystem(CFS)monitorsthecrusherlevel(jawcrusherandconecrusher)ortheloadattherockerandrotoraswellasthemotorutilisation(impactcrusher).

ThecrushersoftheEVOlinehaveaninnovative"diesel-directelectric"driveconceptandarepowerfulandeconomicalatthesametime.Anefficientandpowerfuldieselenginedrivesthecrusherdirectlyviaafluidcoupling.Thedrivetechnologythusimpresseswithextremelylowefficiencylossesandmaximumoutputdirectlyatthecrusher.Allsecondarydrives–forexample,forprescreen,vibratingchutesandconveyorbelts–aredrivenelectrically.Thefluidcouplingguaranteeshighoperationalsafety–foroperatorandmachine.

Asmartoverloadprotection

Duringringbounce,amovementiscreatedbetweenthebowlandthemainframeoftheconecrusherasaresultofexcessivecrushingforces.Thisistriggeredbyfeedsizesthataretoolargeorsmall,anexcessivefinecontentorthecontinuousfeedingofuncrushablematerial.Toprotectthecrusher,softwarecontinuouslymonitorsthehydraulicpressureofthecrusheroverloadsystemandreactswhennecessarywithtwomodes:

ThelinecouplingoptionallowsspecialKLEEMANNplantstobecoupledwithoneanother.Thecrushingprocessbetweenthecrushingplantsisautomaticallycontrolledsothatmaterialisalwaysconveyedwithmaximumefficiencythroughthemachines.Aprobeisinstalledatthecrusherdischargeconveyoroftheupstreammachine,whichmonitorsthefillinglevelofthefeedingunitofthedownstreammachine.Whenthefillinglevelreachesadefinedheight,theoutputoftheupstreamplantistemporarilyreducedorfeedingisswitchedoff,thuseffectivelyreducingtheoverfillingofindividualmachinesandensuringthatmachineutilisationisalwaysideal.ThefeedcontrolContinuousFeedSystem(CFS)alsoguaranteesoptimumutilisationofthecrusher.Forsafetyreasons,thecrushingandscreeningplantsareconnectedphysicallywithoneanotherbyacable.Ifanemergencystopbuttonispressedontheplanttrainintheeventofanemergency,allmachinesaresafelystopped.

Conecrusherscrushthefeedmaterialinacirculatingopeningandclosingcrushinggapbetweenbowllinerandcrushercone.Openingandclosingalsotakesplacesimultaneouslyontheoppositessidesofthecrushingchamber.